the entire world of manufacturing is consistently evolving, pushed by the necessity for enhanced precision, effectiveness, and value-success. 1 technologies that's speedily reworking industries is laser welding. As a number one Laser Welding Machine supplier, we are witnessing firsthand the profound effects these equipment are obtaining on contemporary production processes. This blog put up explores the core Added benefits and advantages of laser welding, demonstrating why it has started to become an indispensable Software for businesses striving to remain aggressive.

Table of contents:

Introduction to Laser Welding technologies

Advantages of Laser Welders more than classic Welding Methods

How Laser Welding devices make improvements to generation effectiveness

Introduction to Laser Welding Technology

Laser welding is usually a fusion welding approach that uses a focused laser beam to join supplies. The high concentration of energy permits deep, slim welds website with minimal warmth-affected zones. This specific Regulate minimizes distortion and damage to bordering supplies. Unlike classic welding methods, laser welding may be used over a broader range of resources, like dissimilar metals, and sometimes needs very little to no filler product. The process is adaptable to automation, enabling for greater velocity and consistency in production. The Laser Welding Machine supplier market place is growing swiftly, pushed with the increasing desire for this adaptable technological innovation.

benefits of Laser Welders about regular Welding solutions

in comparison to traditional procedures like MIG or TIG welding, laser welding offers quite a few essential rewards. First, the precision on the laser beam allows substantially smaller sized and even more aesthetically pleasing welds. Second, the heat-afflicted zone is considerably lessened, reducing distortion and preserving the integrity of the encompassing substance. Third, laser welding is much faster, resulting in improved output throughput. Fourth, it may weld dissimilar metals extra effectively, opening up new design and style choices. at last, laser welding is very automatable, decreasing labor costs and expanding consistency. This suite of Added benefits tends to make laser welding a compelling alternate to classic welding procedures for the wide array of apps.

How Laser Welding devices enhance output Efficiency

Laser welding substantially enhances production efficiency in many approaches. The velocity and precision of the process allow for faster welding cycles, leading to increased creation volumes. Automation abilities additional increase efficiency by lessening the need for guide intervention and reducing problems. The narrow weld seams have to have much less submit-weld ending, saving time and resources. Additionally, the opportunity to weld dissimilar metals simplifies manufacturing processes and cuts down the need for many becoming a member of procedures. For example, Based on information and facts from LatheGlobal, their fiber optic, h2o-cooled laser welding (HW-2000W) gear demonstrates the Highly developed engineering driving this efficiency revolution. The trustworthiness and repeatability of laser welding contribute to constant product or service quality and minimize scrap prices, more boosting overall effectiveness.

In conclusion, laser welding is revolutionizing modern production by providing unparalleled precision, velocity, and efficiency. From aerospace to automotive to electronics, industries are increasingly adopting laser welding technologies to gain a competitive edge. As a Laser Welding device provider, we've been devoted to supplying slicing-edge alternatives that empower corporations to rework their manufacturing procedures. If you are looking to help your production capabilities and stay forward with the curve, contemplate Discovering some great benefits of laser welding. The future of manufacturing is listed here, and It is becoming welded with lasers.

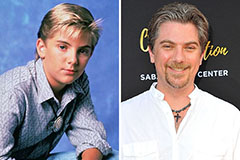

Josh Saviano Then & Now!

Josh Saviano Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Danielle Fishel Then & Now!

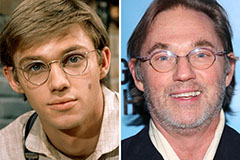

Danielle Fishel Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!